by Everett 2/28/2017

UPDATE BELOW***

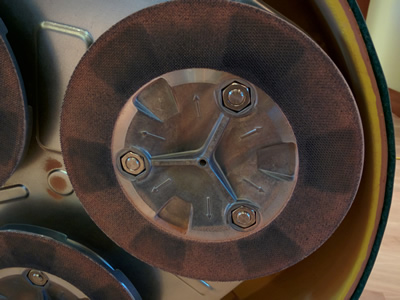

I may be onto another crazy idea. If you look at the driver pads of the Trio you notice a big almost 5 inch hollow spot in the center of them. Also every 1.5 inches or so there's a void on the part that does make contact, but we can ignore that for now. Theoretically speaking, what if the discs on the Trio only made contact with a half inch strip around the outside instead of 1 1/2?

Lets go the other direction with that example. What if it made contact with a 2 inch strip around the outside instead of 1 1/2? It would take a little less time, use fewer pieces, and waste less of the center of each piece. It seems like simple physics, it would make for a better machine. More contact between abrasives and wood flooring is going to be better in multiple ways.

Now lets take it even further. What if the contact area went all the way to the center of the disc and made contact with the full 8 inches? Given the previous examples, to ask the question is to answer it. According to my experience, the square area of abrasives making contact with the floor is the most important factor when determining the effectiveness of such a machine. The other major factors are machine weight, hardness of the pad, and whether the discs free wheel or are driven, but my focus here will be the contact area. Here's a comparison of the contact area between different machines:

-Bona Multidisc, American HydraSand-

6 discs, 5" diameter, 19.625 square inches x6= 117.75 total square inches

-Lagler Trio-

3 discs, 8" diameter minus 5" center, 50.24-19.625=30.615 x3= 91.845 total square inches

-Lagler Trio with steel discs-

3 discs, 8" diameter, 50.24 square inches x3= 150.72 total square inches

-Bona Powerdrive-

4 discs, 6" diameter, 28.26 square inches x4= 113.04 total square inches

As you can see, the steel discs are a marked improvement across the board for all these types of machines. If the machine has soft pads then they will make it more aggressive and actually enable it to flatten floors. When it comes to the Trio, which already has hard metal discs from the factory, they increase the contact area with the floor dramatically. Not only do they fill out that 5 inch void in the center, but the voids around the actual contact strip as well. Frankly I'm surprised that these aren't offered from the manufacturers.

If there's one criticism I could predict it would be the claim that the tight arcs from the center of the discs are going to make an odd scratch pattern. This is a valid concern, but the purpose of steel discs for any machine or buffer attachment has never been finishing smoothly or getting a floor ready for stain. Their primary purpose has been increased aggressiveness and flattening ability. For the multi disc attachments you simply remove them, but the beauty of steel discs for the Trio is that you can easily add the donuts for final passes, and pretty much never take the steel discs off.

What's next, a huge rectangular steel plate for the OBS-18? You never know........

UPDATE***

After putting this theory into practice for a few months, it just hasn't had quite the impact that I thought it would. Recently I decided to take the steel discs off just to try the factory pads again and it actually seemed to do better, why this was the case is something I can't explain. It has even been suggested to me that the voids around the contact area allow you to rotate the sandpaper, so that the parts of the discs that don't make contact can then be used, essentially doubling the life of the abrasives. So I have tentitavely decided to abandon the steel discs for the Trio. I will update this again if anything changes.